WATER / WASTEWATER TREATMENT

WATER / WASTEWATER TREATMENT

Water resource management is crucial as populations grow and awareness of water quality and wastewater treatment improves. Modern technologies and water reuse are essential to meet societal and environmental needs.

The Mixtec group specializes in custom-designed mixing equipment for the water and wastewater treatment industries, offering a diverse range of mixers for municipal installations and projects globally. Our mixers are designed to meet the rapid mixing, flocculation, anoxic, and anaerobic mixing needs of both potable water and wastewater treatment processes.

At Mixtec, our priority is to continually enhance the performance and efficiency of our mixers, delivering increased productivity, longer operational life, and cost savings for our clients. We also provide retrofitting services for existing mixers, backed by full technical and maintenance support through our comprehensive after-sales services. Our team is committed to providing site visits, installation inspections, and hot and cold commissioning services to ensure seamless project execution.

Сhemical Make-Up

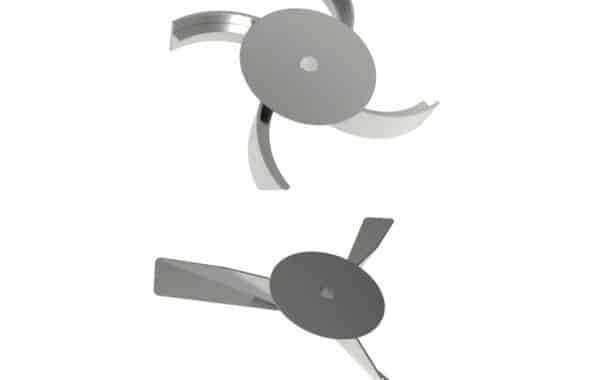

For applications such as lime and aluminium sulphate, our standardised high-efficiency impellers are recommended. These three-bladed axial down-pumping designs are best suited for blending applications, while four-bladed options are available for more aggressive blending requirements. All impellers are designed for low shear, high flow applications.

Flocculation

Flocculation is a highly shear-sensitive mixing application. Unlike most mixing processes, the primary function of a flocculator is simply to keep the water in motion, allowing the agglomeration of particles to proceed efficiently. Our impellers for flocculation are specifically developed to operate at low tip speeds, maintaining low shear and turbulence while generating high axial flow.

We also understand the importance of material selection in sanitation processes. For applications with high concentrations of chemicals such as calcium hypochlorite, our wet ends are typically made from carbon steel lined with fluoropolymer. In most cases, our wet ends are manufactured from 304 or 316 stainless steel to ensure long-term durability.

Anti-Raggings Impellers

Mixtec’s impellers for wastewater treatment feature unique anti-snagging geometries specifically designed to avoid harmful rag entanglement. For smaller fully welded impellers, our backswept blade and ‘bolt-free’ one-piece designs offer anti-fouling properties with significantly lower power draw.

Larger impeller designs incorporate counter-sunk bolts through a keeper plate to secure the impeller to the shaft. These combined axial and radial flow patterns are highly effective for floor scouring and reducing the risk of rag build-up. Additional design features help minimise fouling around the shaft and hub, making these mixers particularly well-suited for anoxic and anaerobic chambers.

Anoxic and anaerobic (BNR)

Our impellers for anoxic and anaerobic processes are carefully engineered to support biological nutrient removal (BNR) by blending nitrates with organic microbiological material. This process is essential for effective denitrification, reducing nitrogen and phosphorus—two primary contributors to eutrophication, algal blooms, and low dissolved oxygen levels that can harm aquatic ecosystems. In anaerobic digesters, our mixers facilitate the stabilisation of sludge by promoting the decomposition of organic and inorganic matter in oxygen-free environments.