RESEARCH & DEVELOPMENT

RESEARCH & DEVELOPMENT

At Mixtec, our team of experienced engineers is dedicated to continuous research and development in our on-site laboratory and fluid handling facilities. With our in-depth understanding of various fluid behaviours and containing vessels, combined with our extensive database of previous applications, we ensure that every Mixtec impeller is designed to operate optimally in your specific application.

Beyond impeller design we offer a range of services with regards to tank design, special arrangements such as anti-vortex baffles, risers, drip tubes, mounting structures, nozzle orientations, and the most economical vessel shape. Our customer design service and fluid mixing laboratory can produce a complete mixer design.

Mixtec is committed to innovation, and our dedicated research and design teams are continuously improving existing systems and developing new product offerings. Our state-of-the-art technology, including Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations, as well as lab and pilot testing, ensure fail-safe designs.

Before any new impeller design is released, we measure and confirm its performance through laboratory and comprehensive industrial tests. Trust Mixtec for expert fluid handling solutions that are designed to optimise your specific application.

Mixtec Laboratory Test Work:

We pride ourselves on our ability to quickly assemble small-scale versions of larger mixers in the field. This enables us to test and analyse problems rapidly and accurately, allowing us to respond to issues faster than our competitors.

At Mixtec, we understand the importance of quality and efficiency in fluid handling. That’s why we continually invest in our laboratories and research and development teams to ensure we provide the best possible service and solutions to our customers. Trust Mixtec for expert testing and analysis, and innovative solutions that are tailored to meet your unique needs.

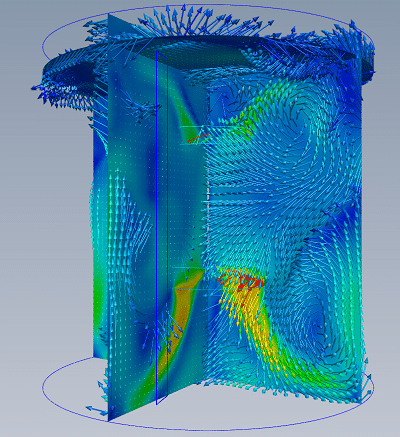

CFD (Computational Fluid Dynamics)

Mixtec employs advanced technology, including computational fluid dynamics (CFD) and finite element analysis (FEA), to design and enhance its products. Through CFD software, Mixtec comprehensively analyses flow characteristics generated by impellers, enabling the creation of highly effective mixers adaptable to any situation. This approach facilitates continuous improvement of impellers, ensuring optimal performance in diverse mixer applications without costly physical test models. By minimising internal costs, Mixtec offers competitive pricing to its customers.

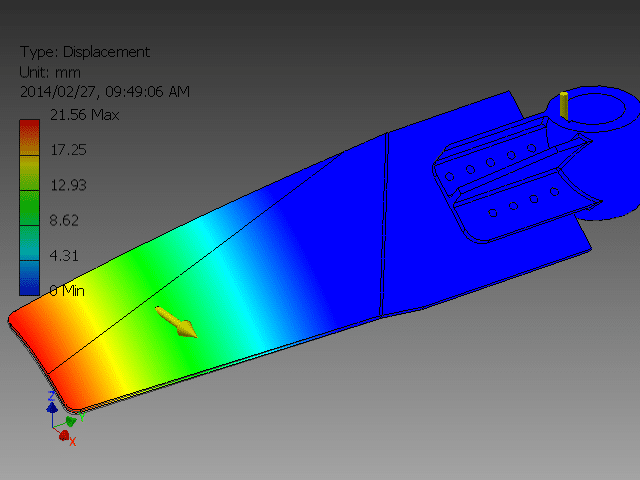

FEA (Finite Element Analysis)

Mixtec employs both CFD and FEA to enhance design durability and reliability in mixing equipment. Committed to continuous improvement, we tailor innovative solutions for diverse customer needs, customising non-standard parts and equipment like tanks, structures, baseplates, pedestals, and impellers. Our expertise and cutting-edge technology ensure tailored solutions for individual client requirements, providing innovative and reliable mixing equipment optimised for specific applications. Trust Mixtec for customised, efficient mixing solutions.