MIXERS & AGITATORS

MIXERS & AGITATORS

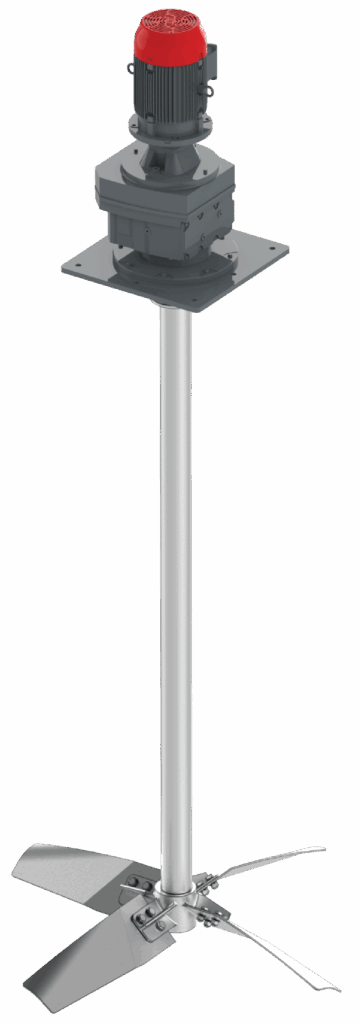

1000 Series

The Mixtec 1000 series consists of versatile, medium-duty Mixers and Agitators designed for open tank applications, and requires base-plate mounting. Offering flexibility, it accommodates various mounting options such as Standard Flat Baseplate, Raised Baseplate (commonly utilised in water treatment), and Angle Riser (at a 10-degree angle). These mixers can be centrally or off-center mounted in tanks with baffles or without, and in vessels featuring conical, dished, or flat bottoms.

During the quotation phase, Mixtec provides a General Arrangement Drawing detailing Live Loads exerted by the Mixer, aiding in the design of a sturdy support structure capable of withstanding these loads. Ensuring rigidity and robustness in mounting structures is crucial to prevent flexing or twisting induced by the Mixer, as weak structures may lead to premature gearbox failure.

4000 series

The Heavy Duty 4000 Series Agitators are specifically engineered for handling larger tanks. These are predominantly utilised in the mining sector where tanks can reach dimensions of up to 20m in diameter by 20m in height.

Mixtec prides itself on delivering large-scale heavy-duty mixers and agitators, often in batches ranging from 6 to 16 units. Primarily serving the mining industry, the most common applications include Oxidation and Leaching, CIL & CIP processes, alongside Neutralisation tanks, Cyanide Destruction, and Surge & Buffer Tanks. Additionally, there’s a growing demand for these agitators in water treatment plants, particularly in the Anoxic and Anaerobic Zones, as well as for Acid Mine Water neutralisation, positioning the 4000 series as a staple in water and wastewater treatment facilities globally.

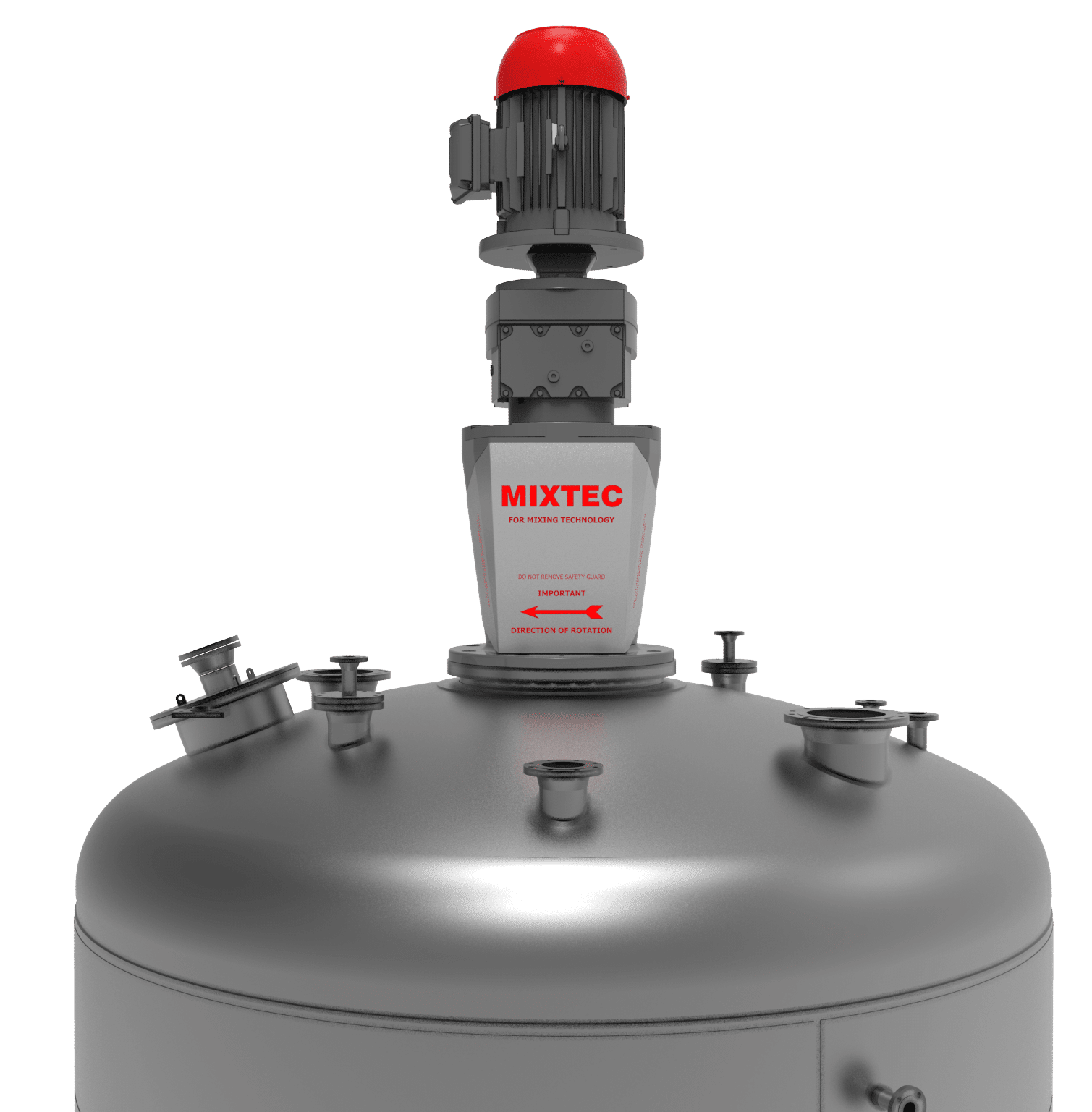

2000 series

Mixtec’s 2000 Series Mixers and Agitators are designed to suit closed and sealed vessels. Different process requirements need different types of seals; Mixtec offers a wide range of sealing arrangements including Lip Seals, Packed Glands, Moat Seals and Mechanical seals as well as mag drive. Depending on the sealing requirements we will Custom design a pedestal incorporating your seal into an easy to maintain drive assembly.

Mixtec utilises the 2000 series when dealing with processes such as Autoclaves, Reactors, Sugar Pan Mixers, Heat Transfer Applications, Mass Transfer

Applications, Bitumen Make-Up and many more.

Depending on the process requirements, our clients can choose an optimal sealing solution:

- Simple lip seal or gland packing for ease of maintenance,

- Single mechanical seal,

- double cartridge mechanical seals,

- moat seal.

250 Series

The smallest drives that we are able to supply come from the 250 series, tailored for applications in smaller industries like paint manufacturing.