DESIGN & MANUFACTURING

DESIGN & MANUFACTURING

At Mixtec, we prioritise quality in design and manufacturing with a thorough pilot testing process. We use Computational Fluid Dynamics (CFD) to validate optimal solutions and conduct scaled-down tests for adjustments before implementation. By collaborating with operators worldwide, we address unique needs and focus on mixer configuration, performance, and mechanical issues. Our advanced software enables precise calculations to ensure safety and efficiency, and we work closely with clients to define project scopes and provide tailored suggestions.

Optimal mixer design starts with the application and/or current installation evaluation. We address the mixer configuration, performance, process, and address mechanical problems that need resolution.

Once the application is clear and the process data is collected and evaluated, principal suggestions are issued and through negotiations with the client the scope of work is decided.

Mixtec utilises advanced in-house software to perform calculations for mixer configurations, focusing on:

- Structural and mechanical integrity, along with safety

- High efficiency, corrosion resistance, and abrasion resistance

- Cost-effective capital expenditures (CapEx) and low operating expenses (OpEx)

We carefully select the mixer and gearbox configurations, impellers, materials, sensors, and accessories, drawing on Mixtec’s extensive experience in process industries and the successful deployment of tens of thousands of agitators worldwide.

Our comprehensive historical database enables us to identify the best solutions for each application.

We are able to work with any Metals. Below is a list of some/but not limited to, common metals we have used:

Metals

Stainless, duplex / super duplex, exotic alloys and special materials (eg. 304L, 316L, 904L (1.4539), Alloy 20, Alloy 31, LDX2101 (1.4162), SAF 2205 (1.4462), SAF 2507 (1.4410), F255 (1.4507), Titanium, Hastelloys, Inconel, Zeron 100, Monnel 400, SAF 2507, SAF 2205, Alloy 20 and others).

Mixtec can work with any Lining / coating. Below is a list of some/ but not limited to, common linings that we have used previously:

Soft Natural Rubber, Chlorobutyl, Bromobutyl, Nitrile, Ebonite, Ceramic, Fibre Glass (GRP), Epoxy Paints. Polishing, Halar, Carbogaurd, E.T.F.E and Ultralar (ECTFE).

Mixtec specializes in engineering and design services, using AutoCAD to create general arrangement drawings and 3D models when needed.

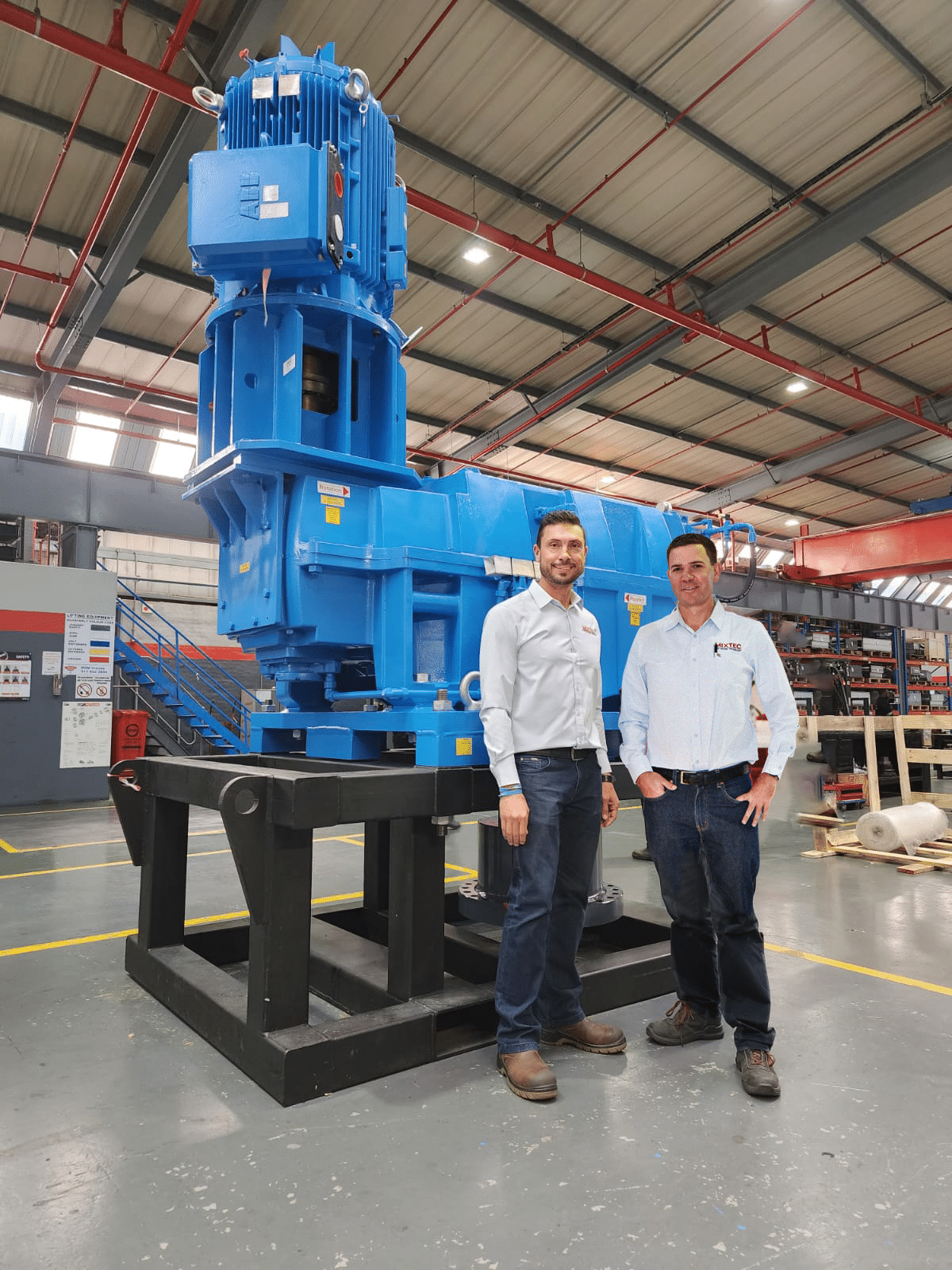

Our Series 4000 heavy-duty agitator drives are designed to handle large mechanical agitators in tanks over 6,000 cubic meters. These systems can support agitators weighing more than 38 tons, with impellers up to 7.6 meters in diameter and shafts reaching 21 meters in length. We offer standard models that exceed 450 kW, and these drives can be easily upgraded to meet specific application requirements.